With regard to protecting the vital components of your magnetic drive pumps, Junty’s alumina bushings offer unparalleled customization options. We understand that different applications require specific materials to ensure optimal protection. That’s why we provide a wide range of ceramic options to meet the diverse needs of our customers.

Silicon Carbide (SSiC/SSiC+C): Superior Resistance to Mechanical and Chemical Damage

At Junty, we offer Silicon Carbide (SSiC/SSiC+C) ceramic sleeves/bushings that provide superior resistance to mechanical and chemical damage. These sleeves are exceptionally durable, capable of withstanding the harshest operating conditions. With our Silicon Carbide sleeves, your magnetic drive pumps are safeguarded against wear and corrosion, ensuring reliable performance and longevity.

Alumina (97%CE/99%CE/99.5%CE): Robust Shield Against Aggressive Fluids

When aggressive fluids threaten the integrity of your magnetic drive pumps, Junty’s Alumina ceramic sleeves/bushings come to the rescue. With alumina content ranging from 97%CE to 99.5%CE, these sleeves offer a robust shield against corrosive substances. Our Alumina sleeves provide excellent chemical resistance, ensuring that your pumps can handle even the most challenging environments.

Zirconia, Tungsten Carbide, and Carbon Graphite: Elevating Performance in Challenging Environments

In challenging operating conditions, Junty’s Zirconia, Tungsten Carbide, and Carbon Graphite sleeves/bushings excel in elevating the performance of your magnetic drive pumps. Zirconia ceramic brings exceptional strength and wear resistance, while Tungsten Carbide offers superior hardness and durability. Carbon Graphite, on the other hand, provides excellent self-lubricating properties. With these advanced ceramic materials, your pumps can operate smoothly and efficiently, even in the most demanding environments.

Ceramic Innovation: Enhancing Longevity and Performance

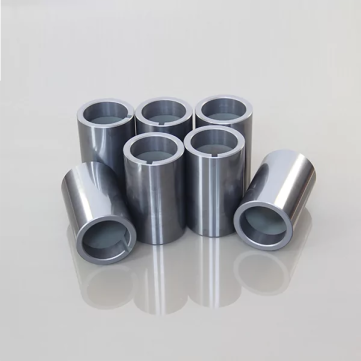

Junty is committed to continuous innovation in ceramic technology, aiming to enhance the longevity and performance of our products. Our ceramic sleeves/bushings are designed to safeguard the running surface of your shaft seals and critical contact surfaces. They provide resilience against damage and abrasive wear, ensuring that your magnetic drive pumps operate at their best.

Fine Materials and Mature Technology: Junty’s Commitment to Excellence

At Junty, we take pride in our commitment to excellence. We utilize fine materials and employ mature technology in the production of our alumina bushings. Our experienced team ensures that every sleeve meets the highest quality standards, providing our customers with reliable and durable products that they can trust.

Optimal Protection for Shaft Seals and Contact Surfaces: Redefining Durability

Junty’s alumina bushings redefine durability by offering optimal protection for your magnetic drive pump’s shaft seals and contact surfaces. With our sleeves in place, you can rest assured that your pumps are well-protected against wear, corrosion, and other forms of damage. Our commitment to providing durable solutions means that your pumps will continue to perform reliably, reducing downtime and maintenance costs.

Trust Junty: Ceramic Sleeves/Bushings for Magnetic Drive Pumps

Regarding ceramic sleeves/bushings for magnetic drive pumps, Junty is the name you can trust. Our high-quality products, customized options, and commitment to excellence set us apart in the industry. With Junty’s ceramic sleeves/bushings, you can ensure the reliability and longevity of your magnetic drive pumps, enabling smooth operations and peace of mind.

Conclusion

Junty’s alumina bushings offer more than just protection for your magnetic drive pumps—they bring high thermal shock resistance, superior thermal conductivity, and exceptional wear resistance. These properties ensure the reliability, efficiency, and durability of your pumps, even in the most demanding applications. With Junty’s alumina bushings, you can trust that your magnetic drive pumps will perform optimally and withstand the test of time.