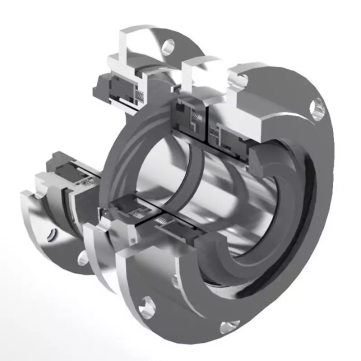

A mechanical shaft seal is a vital component in many industrial applications, as it prevents the leakage of fluids and gases. Junty, a leading mechanical seal manufacturer, offers a wide range of mechanical seal parts, including seal rings, bushings, wear parts, metal parts, rubber parts, rotors/vanes, balls, and special shapes. In this article, we will discuss the benefits of Junty‘s mechanical shaft seal and its various applications.

Junty’s expertise in mechanical shaft seal manufacturing

Junty has over two decades of experience in the manufacturing of high-performance mechanical shaft seals. Our team of skilled engineers and technicians continually works to improve the quality and precision of their products. Junty has a state-of-the-art manufacturing facility and uses advanced techniques to produce mechanical shaft seals that meet the highest standards of quality.

The advantages of mechanical shaft seals

Mechanical shaft seals have several advantages over other sealing methods:

- They have a long working life, which means reduced maintenance costs and increased productivity.

- They have good wear properties, which ensure efficient operation in harsh environments.

- They minimize leakage, which reduces the risk of contamination and damage to equipment.

- They have less friction for the shafts or bushings, which results in less wear and tear on the equipment.

The applications of Junty’s mechanical shaft seal

Junty’s mechanical shaft seals are widely used in various industrial applications, including pumps, compressors, and mixers. They are used in the chemical, oil and gas, pharmaceutical, and food and beverage industries. Junty’s mechanical shaft seals are also used in water treatment plants, power generation plants, and mining operations.

The benefits of Junty’s mechanical shaft seal

Junty’s mechanical shaft seals offer several advantages over other seals:

- They are reliable and durable, ensuring long-term operation and reduced maintenance costs.

- They are designed to withstand high pressures and temperatures, making them suitable for use in harsh environments.

- They are customizable, which means they can be tailored to meet the specific needs of each application.

- Junty offers excellent customer service, ensuring that customers receive the right product and support for their needs.

Conclusion

In conclusion, Junty’s mechanical shaft seal is a reliable solution for various industrial applications. With Junty’s expertise in mechanical seal manufacturing and the advantages of mechanical shaft seals, customers can expect reliable and long-lasting performance. Whether it is pumps, compressors, or mixers, Junty’s mechanical shaft seals offer a cost-effective and reliable solution for all.