Pump bushings play a crucial role in optimizing pump performance by protecting the shaft and ensuring smooth operation. At JUNTY, we understand the importance of these components in maintaining efficient pumping systems. Let’s explore the definition and function of pump bushings, as well as the significance of closer clearances and vibration reduction in their operation. Pump bushings are cylindrical pieces that provide support and reduce friction between rotating components within a pump. They help maintain proper alignment, reduce wear and tear, and enhance overall pump efficiency. Close tolerances between the bushings and the shaft are essential for achieving optimal pump operation. Additionally, effective vibration reduction is vital to minimize stress on the system, extend component life, and prevent failures.

Exploring JUNTY’s Pump Bushing Solutions

At JUNTY, we take pride in offering high-quality pump bushings that cater to the diverse needs of our customers. Our range of products includes various solutions designed to enhance pump performance and durability.

Magnetic Drive Pumps Sleeves/Bushings

For magnetic drive pumps, JUNTY provides customizable options for ceramic sleeves and bushings. These components offer exceptional benefits in terms of wear resistance and corrosion protection. Ceramics provide a superior surface finish and hardness, which helps minimize friction and extend the lifespan of the pump. By choosing our ceramic shaft sleeves, our customers can ensure reliable, efficient, and long-lasting pump operation even in harsh environments.

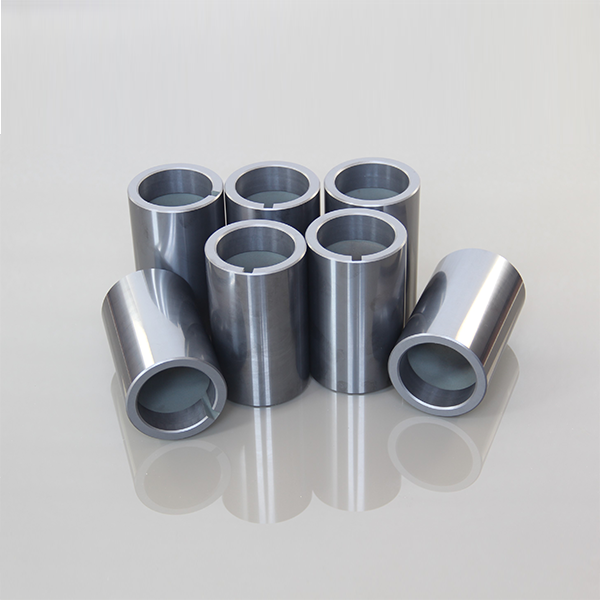

Gear Pump Bushings

Gear pumps are widely used in different industries and require reliable bushings for optimal performance. JUNTY offers gear pump bushings made from various materials, each with unique features to suit specific requirements. With options like silicon carbide, tungsten carbide, carbon graphite, aluminum oxide, and zirconia oxide, our customers can select the most suitable material based on their lubrication needs, operating conditions, and expected lifespan. These durable bushings significantly contribute to the efficiency and reliability of gear pump systems.

Optimal Pump Operation with JUNTY’s Metal-Backed Bearings

In addition to pump bushings, JUNTY also provides metal-backed bearings that further enhance optimal pump operation. Metal-backed bearings consist of a thin layer of bearing material bonded to a steel backing. These bearings offer excellent load-carrying capabilities, improved heat dissipation, and enhanced resistance to abrasion and corrosion.

Our metal-backed bearings provide reliability and longevity to pumping systems. By reducing friction, minimizing wear, and maintaining proper shaft alignment, these bearings enable smooth and efficient pump operation over an extended service life. With JUNTY’s metal-backed bearings, our customers can trust in the robustness of their pumping systems, ensuring uninterrupted performance in critical applications.

Conclusion

JUNTY Pump Bushings and metal-backed bearings are valuable solutions for enhancing pump performance across various industries. Our customization options, including ceramic sleeves for magnetic drive pumps and diverse materials for gear pump bushings, allow us to meet the specific needs of our customers. By choosing JUNTY products, businesses can ensure optimal pump operation, reduced downtime, and extended service life. Trust in JUNTY as your reliable partner to optimize pump performance and achieve exceptional results in efficiency, durability, and reliability.