The application of Al2O3 material is the focus of this blog. Al2O3, a material that has a high strength-to-weight ratio, is slowly becoming more and more popular as it does not require much energy to produce. This is due to the fact that it can be easily melted, purified and poured into a mold. Read on to learn how Al2O3 has become an important stepping stone in all kinds of industries such as mining, automotive and aerospace.

What Is An Al2O3 Material?

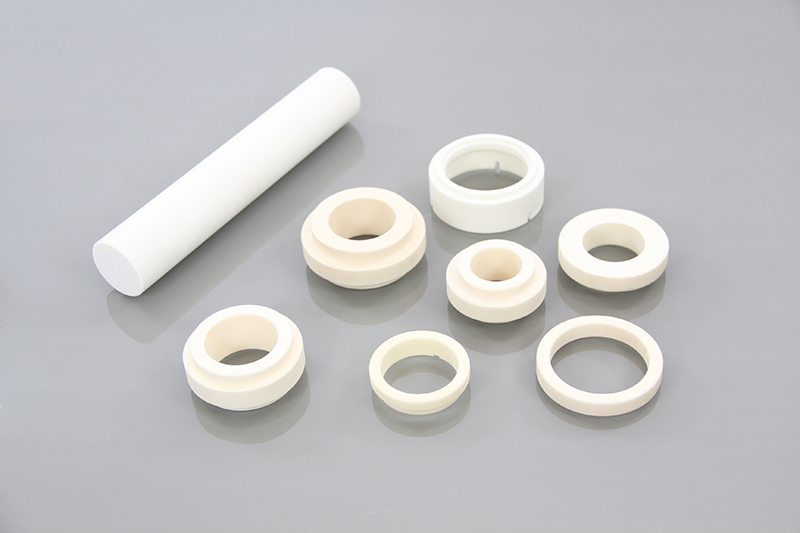

Aluminium oxide, also known as Al2O3, is a material that combines strength and light weight. It is a white or off-white powder that is easily machined and has good thermal conductivity. It can be used in a number of applications, including aerospace and automotive parts.

Benefits of Using Al2O3 Materials

Aluminum is a popular material due to its strength and light weight. It can be used in a wide range of applications, from aircraft to automobiles. Here are some benefits of using aluminum:

-It is strong: Aluminum is a strong metal and can hold up to a lot of stress. This makes it perfect for use in things like airplanes and cars.

-It is lightweight: Aluminum is lightweight, which means it doesn’t use a lot of energy to move or transport. This makes it ideal for things like aircraft and cars.

-It is corrosion resistant: Aluminum is resistant to corrosion, which means it can last for a long time without deteriorating.

Applications of Al2O3 Materials

Aluminum oxide is a material that has been used for centuries. Alumina is a mineral made from the element aluminum, and it is the most common type of alumina. Alumina can be found in many applications, including ceramics and refractories. Alumina is also used to make glass and ceramic composites.

Alumina is strong, but it is also lightweight. This makes it a good choice for products that need both strength and light weight. For example, airplanes use alumina to create their wings. Aluminum oxide also makes good aircraft materials because it doesn’t corrode or tarnish over time.

Alumina is also used in other products because of its properties. For example, alumina can be converted into liquid aluminum using heat and pressure. This process is called “aluminization.” Liquid aluminum can then be turned into various products, such as metals and alloys. This process is often used to create metal parts that are difficult to make using other methods.

Conclusion

In Junty, you can also choose the sealing material you want to use on the sealing device. Al2O3 is a new material that combines the strengths of both aluminum and carbon. The material has already been used in aircraft and automobile engineering, as well as other industries where weight reduction is essential.