Silicon Carbide (SSIC & RBSIC), Tungsten Carbide (6% Nickel TC & 6% Cobalt TC), Carbon Graphite (Resin-impregnated & Metal-impregnated), and Aluminum oxide (95% ceramic, 97% ceramic, 99% ceramic, and 99.5% ceramic) and zirconia oxide are some of the materials we use to make mechanical seal rings and faces.

Rotary Unions Seal Rings

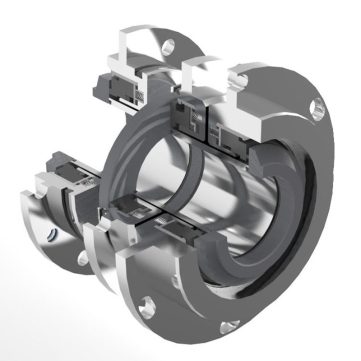

Description

The most crucial component of a mechanical seal, the ring or face, often determines how well and how long the seal will last. Therefore, when designing the mechanical seal ring or face, it is important to consider the material’s rotating and stationary faces, the PCV (MPam/s) data, the installation style, etc.

Depending on the design characteristics, the mechanical seal ring’s or face’s shape can vary greatly. But we can make mechanical seal rings and faces that are both conventional and non-standard, as well as parts that are created specifically for the customer from their engineering drawings or samples.