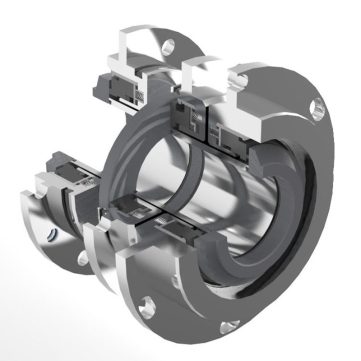

Dry running gas seal is a kind of mechanical seal non-contacting, dry-running face seal, and widely used in high-speed applications. Compressors in a natural gas transfer and distribution network is a common example where dry gas seals are routinely used.

Dry Running Gas Seals

Description

The dry running gas seal is like balanced mechanical seal in structure design. The difference between balanced mechanical seal and dry running gas seal is the seal ring/face design, there are several microns to ten microns deep grooves on the seal face, and usually the face width is wider. The dry running gas seal produce a stable gas film on both sealing surfaces. The gas film has a strong stiffness to completely separate the two seal faces and maintain a certain seal gap, which cannot be too large, generally a few microns. If the sealing gap is too large, the poor sealing effect will increase the leakage. When the sealing gap is small it is easy to make the two sealing surfaces contact, because the friction heat of the dry gas seal cannot be lost in time. If the sealing surface is in contact without lubrication, will cause sealing deformation, surface overheating, caused sealing failure. The existence of the gas film effectively separates the seal face and makes the relative operating of the two-seal face cooling. Also, due to the non-contact operation, friction and wear are greatly reduced, extending the life of the mechanical seal and equipment.

The dry running gas seal is described in the API 617 Standard – for compressors seals, and in API 682 Standard – for mechanical seal for pumps.

The material for Dry running gas seal usually is Silicon carbide (SSIC & RBSIC), Carbon Graphite etc.

The Dry running gas seal is made of different materials including:

Silicon Carbide (SSIC & RBSIC),

Carbon Graphite (Resin-impregnated & Metal-impregnated),