Rising industrial activities across the globe have skyrocketed the need for different types of seals to prevent industrial leakages. One of the most important seals in any industry is the rotary seal, which plays a critical role in the working of pumps and other industrial equipment. Rotary seals are widely used in various industries, including aviation, construction machinery, agricultural equipment, wind turbines, medical, automation, fertilizers, and, for that matter, every industry where pumps and fluid transfer equipment are used.

This means that compromising on the quality of seal rings is just a disastrous approach since a low-quality seal ring will not only contribute to industrial losses but also contaminate your expensive equipment, which will increase your maintenance cost. But whenever you have to get your hands on any rotary seal, you need to keep a few things in mind. For instance, what is the material of that seal, and what are its recommended working conditions? Is the seal perfect for your specific need? Only when you get the answer to these questions will you be able to get the perfect mechanical seals.

Bad Impacts of Improper Sealing

You are prone to two losses if you fail to use proper rotary sealing rings.

Firstly, the inefficient sealing rings trigger the fluid leakage, which were supposed to closed between the shaft and stationary parts. This leakage means that the fluid can contaminate your final products, thus reducing their quality. Therefore, your customers will start questioning your products, which is never a good sign for any industrialist.

Secondly, poor sealing rings mean that you will take more time on the after-market, which is detrimental to your equipment and the quality of your products.

Common Signs of Damaged Sealing Rings

But the good news is that the damaged seal rings are always detectable, so you can change them before it’s too late. Some of the common signs of poor rotary sealing rings are:

-

- Leakage

First of all, if you can see the fluid leaked from the hole mechanical seal, that means the seal rings were worn or abnormal broken.

-

- Stopped Running

Secondly, some abnormal broken maybe is the seal rings cracked,this could take the shaft stopped running.

-

- Abnormal vibration

If the abnormal vibration exist persistently,you should check the whole mechanical seal and adjust the seal rings to right area.

Selection Tips

Whenever you have to select the rotary shaft seals, you need to take the following factors into account:

-

- Choose Material Based on Applications Domain

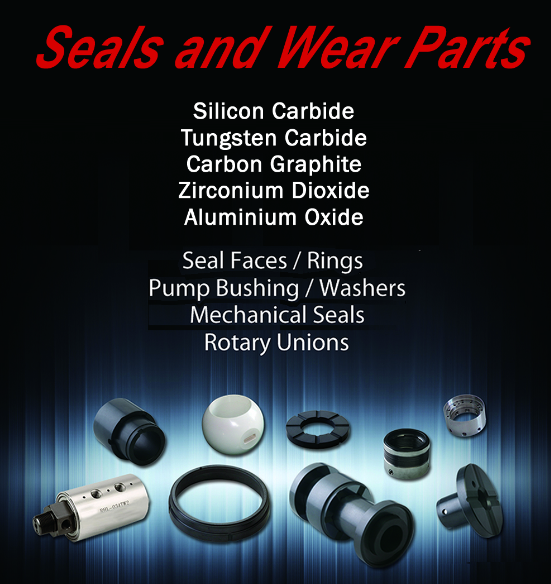

One of the most important things while purchasing rotary seals is the speed of the shaft or the motor. For high-speed shafts, Silicon Carbide is the recommended material for rotary seals. These seals allow you the minimum friction and wear and tear. On the other hand, ceramic seals are also used for low-speed applications.

-

- Buy from manufacture channels

While buying rotary seals, another important point to consider is to get them from an experienced vendor who has proven experience in providing such seals to different industries.

-

- Checking and verification

Whichever model of rotary seal you are about to buy, you can always check it on your specific equipment. Many vendors will provide you with a sample of the actual product or the design specifications, which will allow you to verify whether the product will suit your needs or not.

Wrapping-up

Founded in Chicago, Illinois, Junty has managed to impress industrialists worldwide. Today, Junty enjoys the overwhelming support of global industries in various domains, as our seals and wear-resistant equipment continue to help them in making their operations smooth. As we are a professional mechanical seal manufacturer, complying with the individualized needs of the customers is our specialty since we understand that almost all industries need custom seal rings.

So, for more information about rotary seals, please visit our website.

And for more inforamtion related to the basic information about pump seals, you can read: https://sealchina.com/blog/the-top-3-major-reasons-to-the-failure-of-pump-seals/