In manufacturing bulk materials, A rotary seal is a vital component of the production procedure. Its main goal is to limit product loss and protect the products during manufacturing. The rotary seals, or rotary shaft seals, have mainly two functions. Firstly, they prevent dirt, dust, and water from getting into the installation and stopping the shaft from turning. Secondly, they can prevent fluids (such as grease or oil) from escaping the installation and contaminating the surrounding area.

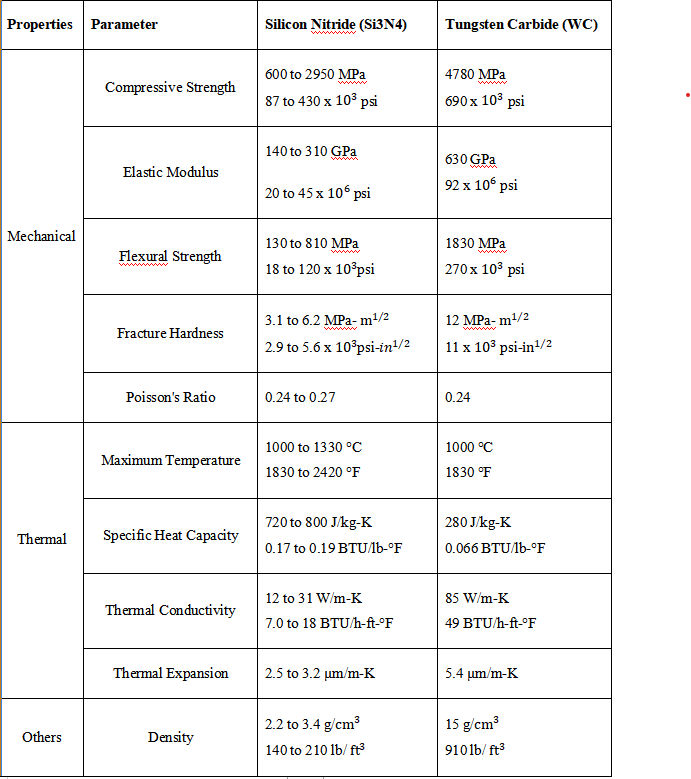

Silicon nitride is one of the non-oxide engineering ceramics in the database that can have a low thermal conductivity. On the contrary, tungsten carbide has the highest fracture toughness and the lowest heat capacity among engineering ceramics that do not contain oxides. It also has the highest density.

To find out which is better for you, silicon nitride or tungsten carbide, keep reading until the end of this blog post.

The Properties Comparison: Silicon Nitride VS Tungsten Carbide

Mechanical ceramic materials like silicon nitride and tungsten carbide are both non-oxidizing. But there are some considerably dissimilar densities between the two materials. Those are:

Top 4 Signs For Replacing The Rotary Seal Rings:

After notifying the differences between the materials, it boils down to one question — when to replace the mechanical seals? There are some warning signs to tell that the rotary rings should be replaced soon. Let’s have a quick look at the following:

1. The Seal Has Notches or Grooves:

If there are notches or grooves on the front of the seal, it signals that the rotary seal rings may be under high pressure, leading them to break soon.

2. Noises Like Popping or Squeaking:

If your rotary seal rings make a squeaking or popping sound when they’re working, there may not be enough liquid to lubricate the seal faces. To fix this, you should either increase the size of the flush line or replace it soon.

3. Tracking with Uneven Wear:

A pattern of uneven wear is a sign that the rotary seal ring has been distorted by being too tight, gripped too hard, or put under too much pressure.

4. A Seal Ring That Is Broken or Damaged:

The seal ring can break or chip if the rotary seal parts are not put together correctly or are managed incorrectly. To fix this permanently, you can replace it with a new one.

Conclusion:

The two rotary seal rings have some benefits and limitations, which are discussed above. Based on market research, tungsten carbide is more cost-effective and has a higher density than silicon nitride rotary seals.

Now, if you’re looking for a premium-quality and longer service life in the rotary seal parts, go to Junty – A leading mechanical seal & O ring manufacturer and supplier with over 20 years of professional experience.

Because Junty’s reliable mechanical seals, such as seal rings, wear parts, bushings, metal parts, rubber parts, and rotary unions, are all made of high-performance materials, including tungsten carbide, stainless steel, PTFE, FFKM, etc.

Also, the good news is that you’ll get your desired mechanical seal parts within your reasonable budget from Junty.

Need any help? Contact us today. Thanks for reading.