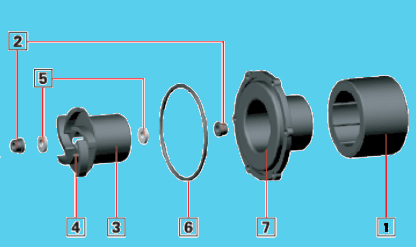

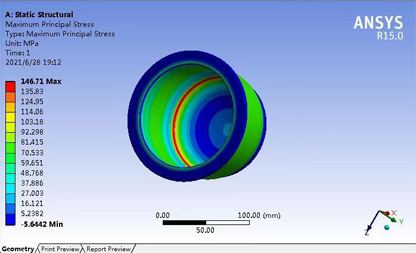

Discover the innovative functionality of our containment shell, a crucial separation component between the external magnet (Drive magnet) connected to the motor and the internal magnet (driven magnet) attached to the impeller. This seal-less solution ensures reliable, leakage-free sealing, eliminating concerns about mechanical seal failures over time.

In contrast to commonly used metals, our containment shell excels in heat management, generating no heat through magnetic induction. Trust in this advanced solution for efficient and dependable containment in your applications. Choose JUNTY for cutting-edge containment shell technology, ensuring optimal performance and longevity.